KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

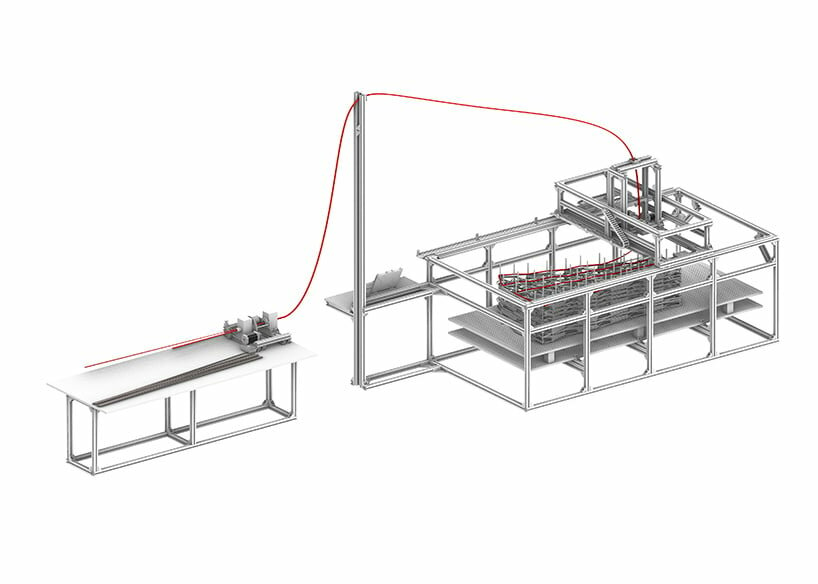

happening now! witness how the swedish family-owned company, bolon, is breaking new ground with exciting material inventions, where all their products now contain 68% waste material, and 0% climate impact per square meter.

PRODUCT LIBRARY

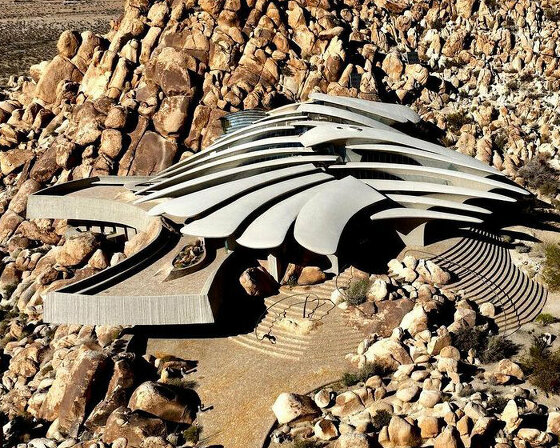

take a look at the late architect’s most iconic works, including the high desert house in joshua tree and hoshino stone chapel in japan.

connections: +1570

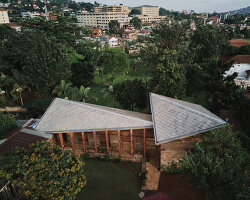

the pavilion, with its large aluminum-coated disc canopy, demonstrates the architect's trademark geometric integration into the natural environment.

connections: +390

the home's complex, latticework facade of earthen tiles integrates over 6,200 discarded plastic toys.

a social advocate of establishing kinship between public and private realms, yamamoto is the 53rd laureate of the pritzker prize.

connections: 29